Henry Ford was a revered American business magnate whose name is easily identified with early 20th century American industrialism. He founded Ford Motor Corporation in 1903 and was instrumental in popularizing the consumption of automotive vehicles in the United States and positioning his country as a significant player in the global automobile industry.

It was in 1913 when Ford introduced the moving assembly line. This manufacturing process allowed faster and inexpensive production of vehicles. It also revolutionized manufacturing outside the automobile industry with the introduction of Fordism—a concept and practice that revolves around mass production of inexpensive goods and high wages for workers.

The Moving Assembly Line: The Contribution of Henry Ford in Manufacturing

The moving assembly line is a key contribution of Henry Ford in manufacturing. Note that this manufacturing process involves assembling several parts in a step-by-step fashion. Each part moves from workstation to workstation, and with every movement, several parts were assembled together until they become whole. In other words, parts are added or assembled in sequence until a final assembly is produced.

In his autobiography “My Life and Work” first published in 1922, Ford explained the three principles of assembly. The first one involves placing tools and workers in the operation sequence so that each part travels the least possible distance while in the process of finishing.

The second principle involves using work slides or some other form of carriers so that when a worker completes his or her operation, he or she drops the semi-finished assembly always in the same place. The third principle is about using sliding assembling lines by which the parts to be assembled are delivered at convenient distances.

A key advantage of the moving assembly line is that it allows faster assembly with less labor than having workers carry parts to a single and central workstation. It also takes advantage of compartmentalized work through the division of labor within the workforce. Ford Motor was able to produce larger outputs using this manufacturing process inexpensively.

Note that several small automakers emerged in the U.S. between 1890 and 1910. Ford Motor competed with these manufacturers. However, through the implementation of the assembly line in its manufacturing process, the company was able to outcompete other automakers. The process became a valuable factor of production.

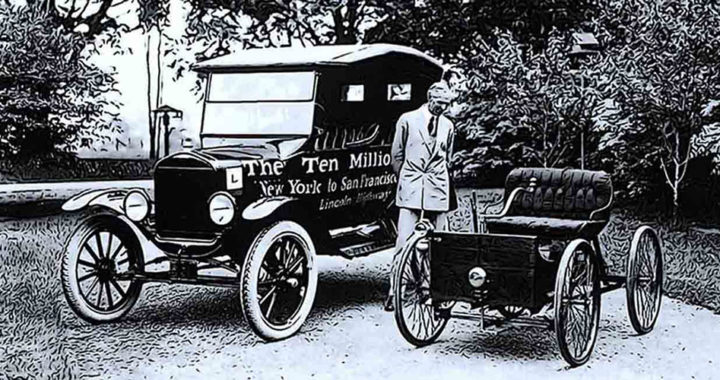

Ford Motor introduced the Model T in 1908. This was a remarkable vehicle. It was simple and light but durable enough to drive on primitive roads. The moving assembly line made this vehicle more popular. Because the novel manufacturing process allowed cost-effective and time-efficient mass production, the company lowered the unit price of Model T and made it affordable for the average consumer.

Fordism: The Socioeconomic Contributions of Henry Ford in the United States

The moving assembly line immediately became a manufacturing norm around the world. During the 20th century, manufacturers from different industries and sectors were able to lower their operations cost while maintaining desired production levels. It also standardized mass production.

In the United States, this manufacturing process improved the profitability of manufacturers, thus allowing them to expand their operation, hire more workers, raise salaries, and lower the price of goods. The greater impact was economic growth driven by industrialization.

Henry Ford and other manufacturers fueled the American economy by improving productivity. They also raised standards of living by creating more high-paying jobs. It is essential to highlight the fact that Ford employed a concept that revolved around mass production of inexpensive goods and high wages for workers. Other manufacturers followed suit. Observers called this concept Fordism.

Fordism is a notable contribution of Ford to the American society and economy because it led to the emergence of novel business practices and considerations that affected the social and economic profile of the U.S. The concept sparked the creation and expansion of businesses, as well as the reduction in the unemployment rate and poverty. Of course, at the micro-level, the concept afforded local manufacturers with a competitive advantage against their foreign counterparts.

The 1998 documentary “People’s Century: On The Line” produced by WGBH Boston illustrated the socioeconomic impacts of Fordism. For example, the opening of a Ford factory in Detroit during the 1900s resulted in a population boom as workers and their families migrated to grab the available job opportunities.

In addition, the social composition of Detroit and other similar cities changed as people from different ethnic backgrounds and cultural heritage became part of the larger workforce. Note that a typical Ford factory employed white Americans, African-Americans, and migrant Germans and Italians, among others.

Mass consumption also became the norm. The 20th-century American industrialization also marked the emergence of the American consumer society. Companies such as Ford Motor granted workers with buying power enough for them to consume non-necessity goods. These workers could actually buy a Ford vehicle.

Major Drawbacks: The Downside of the Moving Assembly Line and Fordism

The positive contributions of Henry Ford in manufacturing and the overall American socioeconomic landscape were undeniable. But there were drawbacks. Ford Motor and other manufacturers limited the freedom of their workers to join labor unions in an attempt to keep them from protesting against policies and working conditions. However, in exchange for this limited freedom, these industrialists and capitalists promoted the importance of having high salaries and the possession of material objects. In fact, Henry Ford encouraged his workers to set aside a part of their wages to save up for a new car.

There were an initial excitement and acceptance over the new socioeconomic setup. However, the revitalized business or manufacturing processes created a workplace environment that was boring and taxing. Furthermore, the compartmentalization of work processes and division of labor brought by the moving assembly line alienated workers. People soon became unhappy and dissatisfied despite their higher standards of living.

According to the book “Levels of Socioeconomic Development Theory” by David Jaffee, the concept of alienation, originally proposed by Karl Marx, is a natural result of industrialization, mainly because of the division of labor and functional independence. This creates powerlessness, meaninglessness, and social isolation. The documentary “People’s Century: On The Line” also featured several former Ford workers who mentioned that doing the same repeated job for several hours a day made their jobs unexciting.

In summary, although Henry Ford was partly instrumental in fueling economic growth and improving standards of living, the manufacturing process and concepts or practices he popularized resulted in the exploitation of workers.

His industrialists and capitalists contemporaries also stirred the creation of values or norms that leaned toward materialistic tendencies, thus paving the way for the emergence of consumerism. Of course, it is still important to note that consumerism is a necessary consequence of industrialism, capitalism, and free-market competition.